Sarp Biocare Ice Machine

- Home

- Sarp Biocare Ice Machine

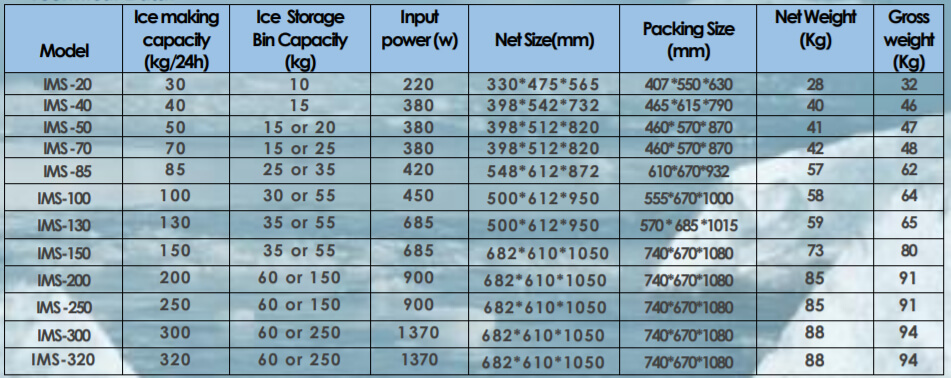

Technical Data:

Features:

- Microprocessor controlled, fully automatic machine to produce irregular size granular flake type of Ice

- Clear visual LED indicator for running status, Low water, Low refrigerant or any other fault.

- Stop and resume automatically through sensors if electric goes off or low water or bin full of Ice

- Stainless Steel Interior and exterior and storage bin is insulated to reduce melting of ice.

- Available with Adjustable legs or caster (depending upon size/capacity of the model)

- Copper alloy freezing cylinder with Powerful crusher to makes 80% hard Ice flaks

- Quoted with Silver Agion for Antimicrobial protection for contamination

- Auto back flushing for self-cleaning of drainage, water chamber and ice cylinder

- World famous vibration less hermetically sealed compressor and air cooled condenser

- Cooling Capacity : approx. 3000 Btuh/W Powerful crusher to make hard Ice

- CFC / HCFC free refrigerant (R134a or R404) Echo-friendly to environment

- Operating Ambient temperature 15 °C to 42 °C and operating Water temperature -10 °C to 40 °C

- Low Noise below 45 dBA ,Low Water and Low electricity consumption

- Water supply inlet for ¾” dim with approx.1-6 bar pressure

- Waste water drain to protect contamination inside storage bin.

- All above Models are based on 220V/50HZ

As summarized

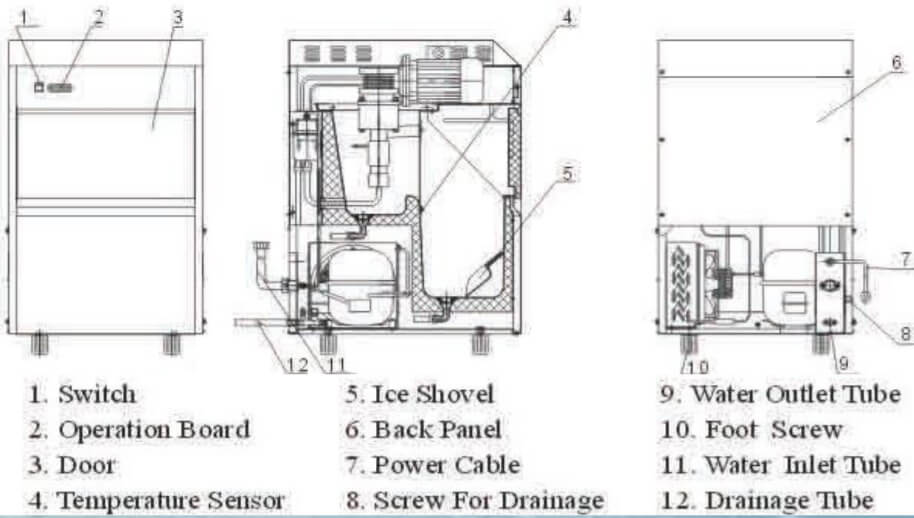

Automatic flake lce makers have been designed in cubic shape with the curved front panel with curved disappearing type of door (or stainless steel flat front panel & flat door for bigger capacity models) for nice appearance. Many advantages of the ice maker are available such as making hard ice quickly, wide ice making capacity, irregular flake type ice shape and ice dropping quickly in storage bin.

Tap water inlet->water incoming-> ice making-> crush ice-> ice dropping-> ice storing.

All the processes are automatically controlled through microprocessor controller and sensors for ice making continuously. In case of water shortage or ice full in cabinet, the indicator on the operation Board will light on accordingly and the ice maker stops operation automatically. The ice storage cabinet is insulated with PUF, so it prevent the ice made from melting. Also, the remaining water after ice made each tune is used for recycling, so not only the water is saved, but also the ice making efficiency is enhanced and the energy consumption is reduced & the customer’s lce making cost is also reduced much. Either purified water or the tap water could be used for ice making.